A Real-World Instrumentation Project

Article originally published on my LinkedIn.

During my professional training, one of the most important subjects was Industrial Instrumentation. We studied the physical principles behind measuring level, flow, pressure, temperature, humidity, and more. We also covered instrument selection and P&IDs.

At university, sensor selection felt linear: weigh variables, choose a device, done. Real life is different. This story explains what happens when theory meets constraints.

What are we measuring?

Palm oil (specifically olein) is a viscous liquid. Best practices recommend heating and stirring to avoid solids and keep the product homogeneous. Foreign materials should be avoided to prevent oxidation and rancidity.

So the question is: What measurement principle would you use to measure level in a large, constantly agitated tank?

Which instrument do we have?

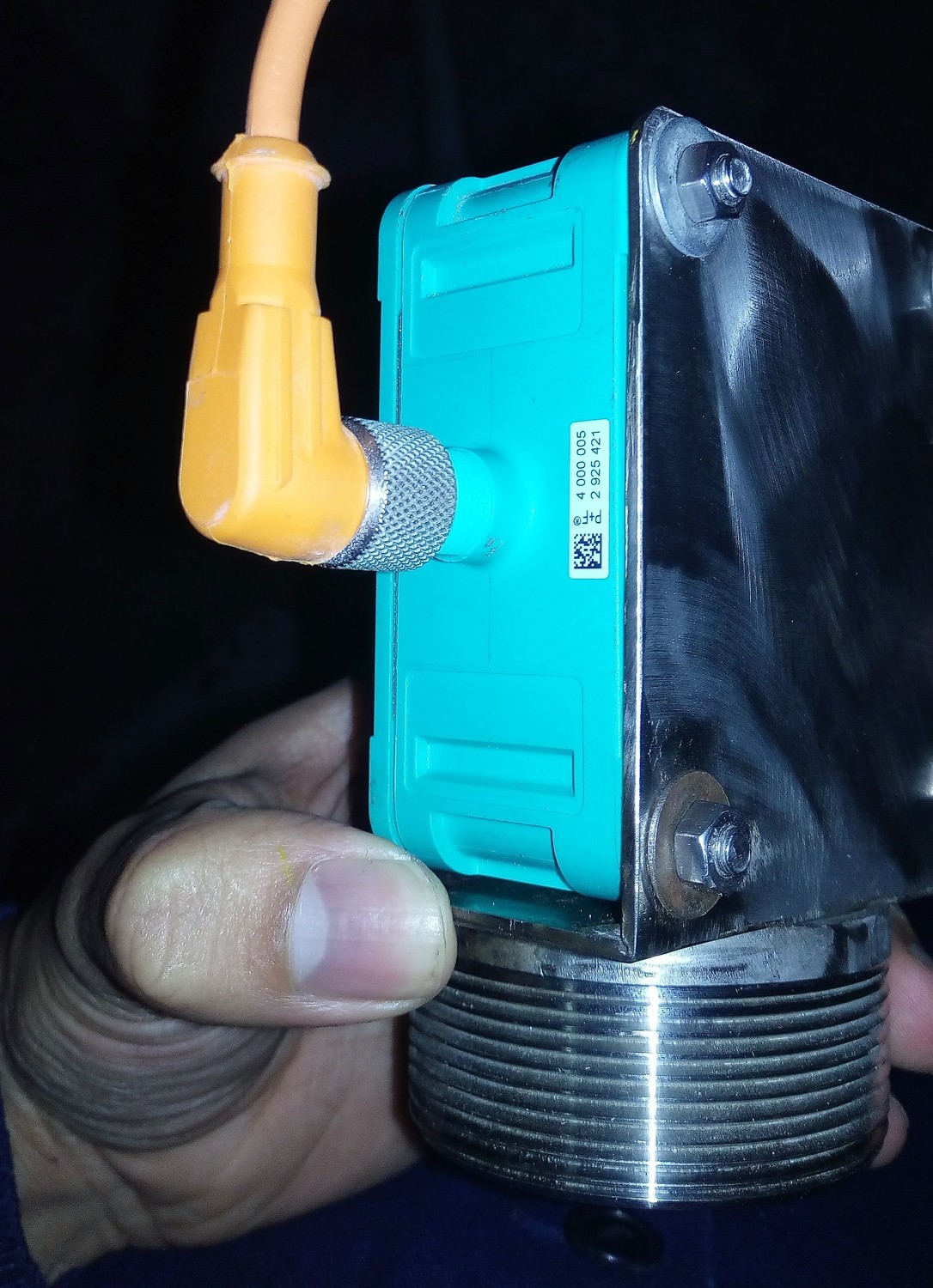

The team before me selected a Pepperl+Fuchs ultrasonic sensor, to be installed on a 2" NPT port at the top of the tank.

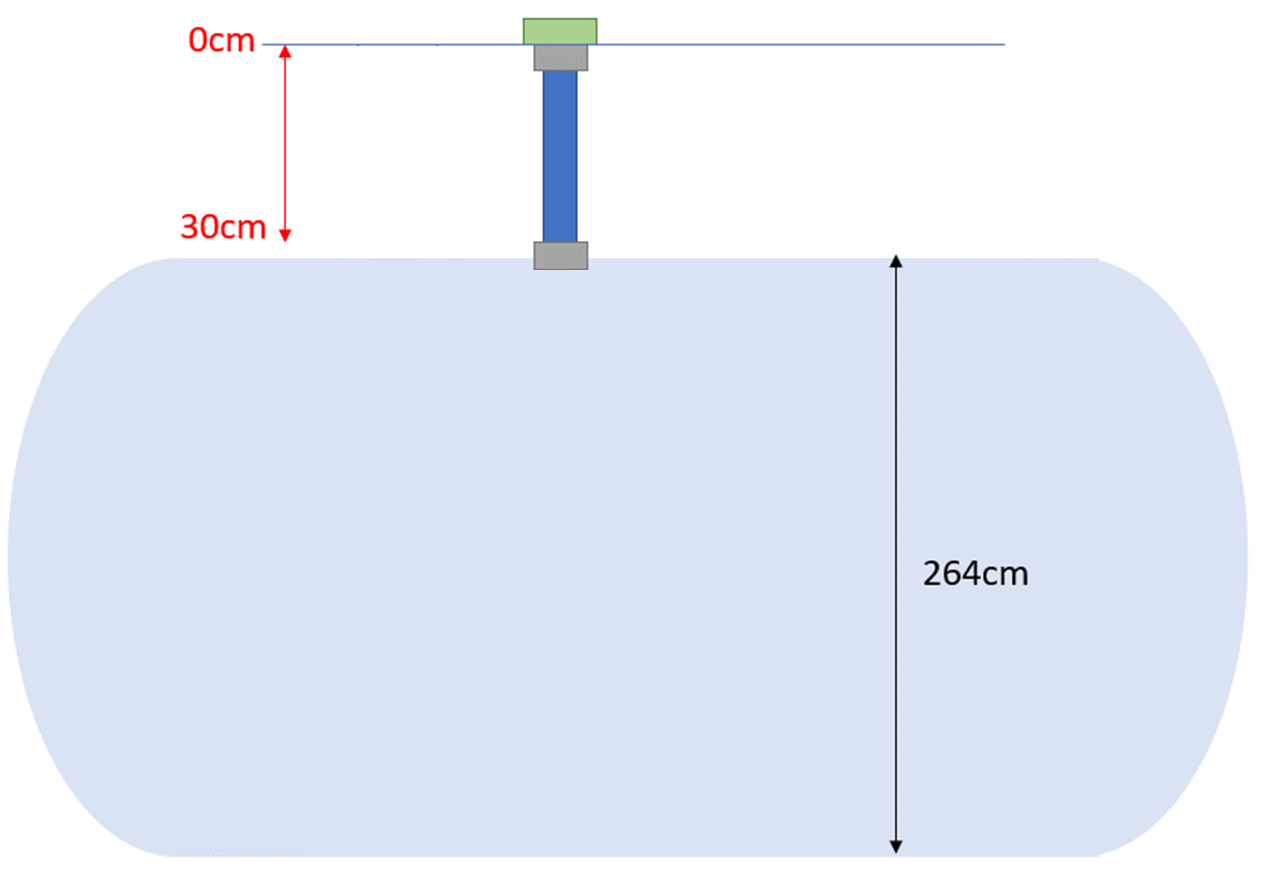

The initial base was wrong: the ultrasonic membrane must face the interior. There was also a 24 cm dead band. Losing 24 cm of headroom is losing over 4000 liters—about two days of production.

Elevating the sensor by 30 cm worked only when the liquid was still. With agitation, readings became unstable. Time to revisit the principle.

How ultrasonic sensors work

Ultrasonic sensors emit a sonic pulse and measure the echo time to calculate distance. They are sensitive to spurious echoes and turbulent surfaces, which distort the return signal.

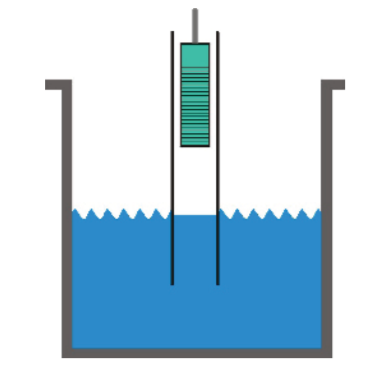

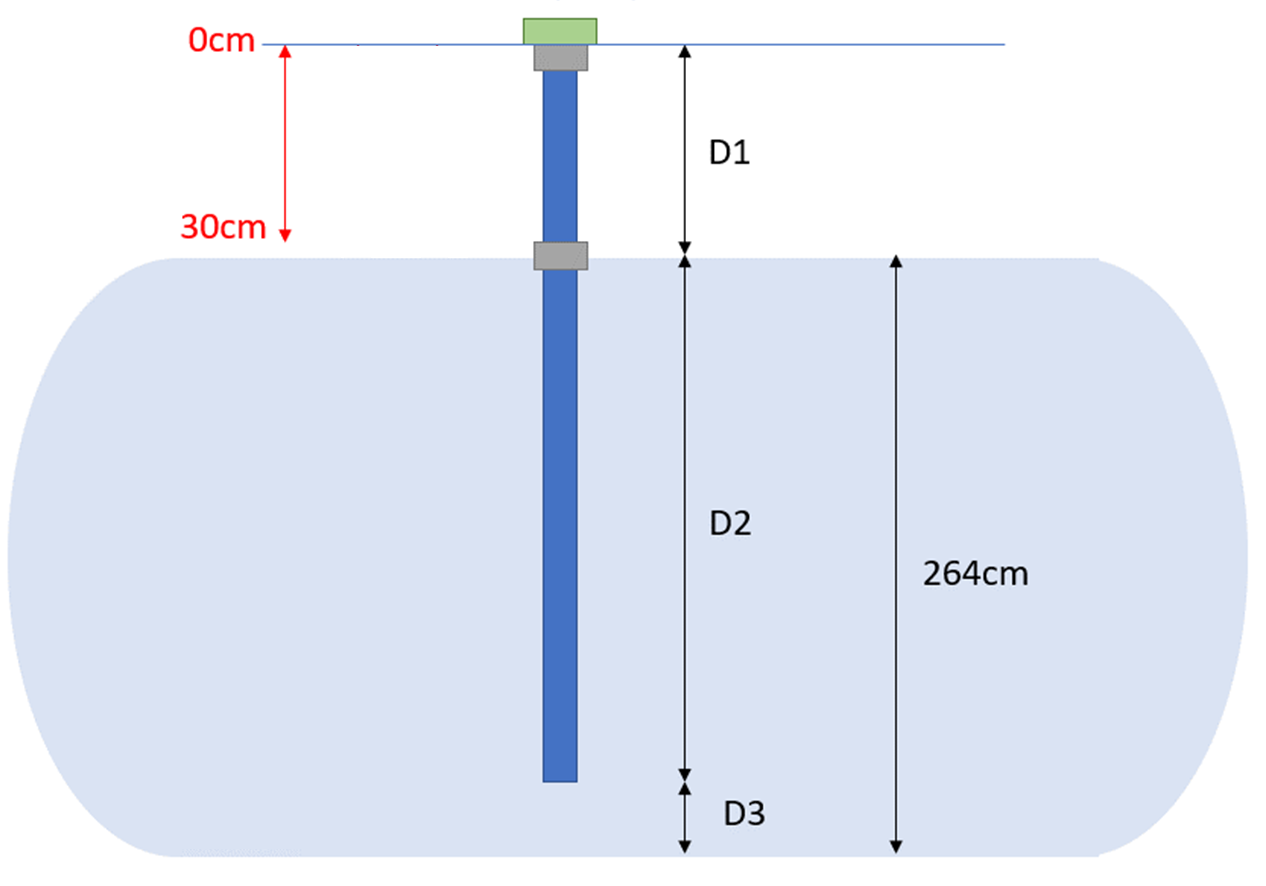

Stilling Tube

A stilling tube confines a calmer column of liquid, creating a stable surface by communicating vessels. It solves turbulence but introduces its own constraints: smooth interior, diameter > 2", centered sensor, no irregularities.

We used PVC for economic, chemical, and physical reasons (smooth interior, machinable threads). After careful threading and sanding to ensure a smooth joint, the sensor produced stable, accurate readings.

Takeaways

- Understand the process first; sensor selection follows.

- Document iterations and constraints—they’re part of the solution.

- The simplest hardware change (a stilling tube) can solve a complex measurement problem.

References

- Storage of Palm Oil

- Lipid Oxidation

- Ultrasonic sensors in pipes